Commercial Egg Grading: The importance of transfer point impacts on egg quality

The quality of a product determines its acceptability to potential consumers. Egg quality is determined by the internal quality of the egg, weight and the condition and appearance of the eggshell. Grading eggs by quality is critical for consistency in food safety and to facilitate uniformity, packing and pricing. Grading affects the profit margin for commercial egg producers.

During the grading process, eggs are transferred from one point in the egg grading machine to another. This article investigates the influence of impacts caused by these transfer points on the quality of eggs.

1. Transfer points in egg grading machines

The introduction of mechanical, electronic and automated egg grading and packing machines has made vast improvements in the consistency and quality of eggs supplied to the market by commercial egg producers. Modern egg grading systems have numerous transition points where eggs are transferred from one point in the sorting system or carousel to another.

Figures 1 & 2: Transfer of eggs using suction cups (left) and carousel (right). The green Vencomatic electronic eggs measure the impact force, as recorded on the Gregg mobile application

Typical egg transfer points make use of suction cups in a suspended cup-conveyor system (see Figure 1) to move eggs from one point (Figure 2) to another or grading points in the system. Bucket elevators, lift systems and rod and curve conveyors are also used during grading, and each of these present a potential impact point.

It is essential that all transferring of eggs occur with utmost care to ensure smooth egg conveying and, thus, minimal damage to the delicate eggshell.

2. Measuring the impact force of transitions on eggs:

The force of an impact on an egg can be measured in Newtons. Using a set of 10 Vencomatic electronic eggs, the impact force on the eggs can be measured at every transfer point in a grading system. Should the impact in Newton measured by the electronic eggs be higher than the force in Newton required to crack the egg (typically

> 40 N), there is a strong likelihood that hairline cracks may occur at the point of impact. The impact on eggs by the egg transportation system can be measured across several impact points to identify the specific points where the impacts were higher.

The De Heus technical team carried out a series of tests on egg grading systems across South Africa to assist in monitoring the impact force on eggs. The tests were done as follows: 10 electronic eggs were used to measure every single transition in the egg transportation system. All transition points were measured individually so that the force at every transition could be determined. Where necessary, the transfer points were adjusted (fine-tuned) with the help of a grading system specialist.

The impact experienced by each egg was determined in Newtons, and the average result of all 10 eggs was converted into a grade from 0 to 10. 10 means that the impact was very low, and 1 means that the impact was very high. See Table 1 for a summarized explanation of the grade scoring system. The higher the impact on the eggs, the lower the score.

|

G-force |

Score |

Colour |

|

>40 |

1 - 3 |

Red |

|

30 - 40 |

4 - 5 |

Orange |

|

20 - 30 |

5 - 6 |

Yellow |

|

<20 |

>7 |

Green |

Table 1: Grade of the measurement

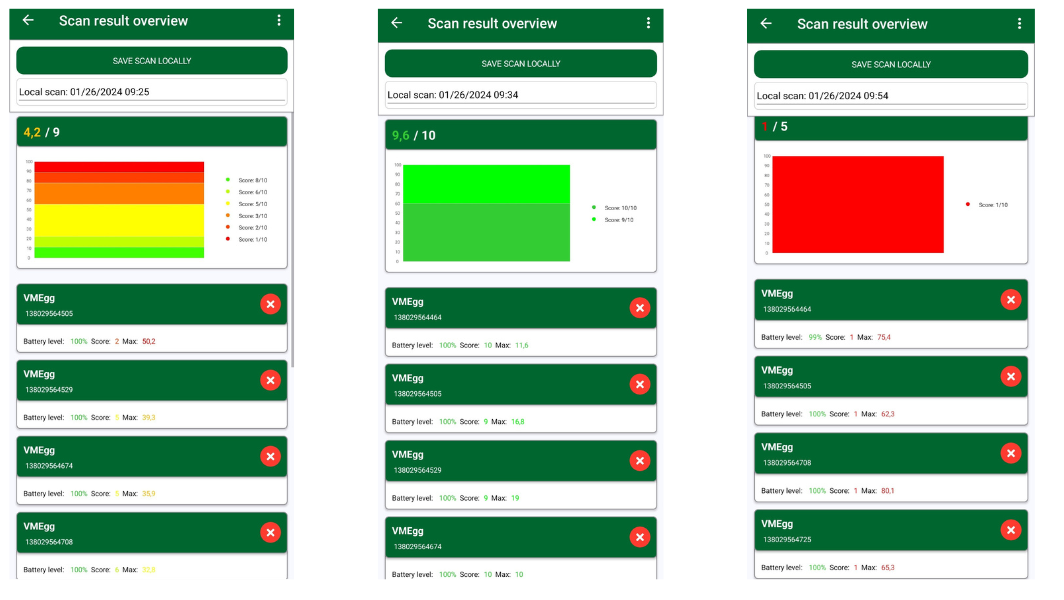

The measured impact on the electronic eggs is illustrated in the figures below. Figure 3 below shows the impact of a cup-conveyor system (Transfer Point A) on 9 individual electronic eggs placed randomly in a tray of 30 eggs. The results showed that the impact ranged from a score of 1 (very high impact) to a score of 8 (low impact), indicating that some of the suction cups at this transfer point were possibly causing hairline cracks.

In comparison, Figure 4 shows a separate cup-conveyor system later in the grading system (Transfer Point B)

with a near-perfect average score of 9.6 was achieved, indicating no impact on the eggs.

To pinpoint the area of concern shown in Figure 3, each 5-egg row in the cup-conveyor system of Transfer Point A was tested individually. Figure 5 shows the row that was found to have high impacts on the eggs, some of which were recorded to be >80 N. Considering that most eggs have a breaking strength of >40 N, an impact force of 80 N is very likely to cause at least a hairline crack, if not a complete breakage of the impacted egg.

![]()

Figures 3, 4, & 5: Impact testing results on Transfer Point A (Fig. 3), Transfer Point B (Fig. 4) and a suction cup row with high impacts in Transfer Point A (Fig. 5)

3. Consequence and prevention

Transfer points in grading systems with high impacts may increase the percentage of eggs with hairline cracks, thus reducing the quality and grade of the affected eggs. This will ultimately affect the profitability of the business if not corrected, as damaged eggs fetch a much lower price.

If the impact point is before the crack detection system of the grading system, these eggs will be separated and may have to be sold as liquid eggs. However, if a transfer point causes high impacts on eggs after they have already passed through the crack detection point, the affected eggs may be packaged and sold to the consumer. Should this happen, egg returns and financial losses will increase, and the business may suffer reputational damage if the numbers are high.

To prevent negative effects on egg quality, consistent monitoring of impact points in grading systems can serve as an early warning should any given transfer point begin to cause higher than-acceptable impacts when transporting eggs. Often, these impacts can be caused by something as simple as the build-up of dust and debris in the suction cups, resulting in the eggs being dropped earlier or later than intended. In this case, frequent cleaning and replacement of the suction cups in the cup conveyor can fix or prevent the damage.

Other causes, such as the timing of the grading system transfers, may require a specialist to visit to fine-tune the system. Testing impact points before and after a grading machine's servicing can be an efficient way to minimize impact-related eggshell damage during grading. Any reduction in the incidence of hairline cracks can significantly impact profitability.

Conclusion

Frequent monitoring of the transfer point impacts in commercial egg grading systems has a large effect on the prevalence of hairline cracks and, thus, the quality and grade of eggs. Egg quality affects the profitability of commercial egg production. Ensuring gentle egg transitions during the grading process is vital in delivering a high-quality end product to the market.

Should you require more information relating to the importance of transfer point impacts on egg quality please contact your nearest De Heus Technical Specialist - https://www.deheus.co.za/meet-our-team/.