Mycotoxins in livestock feed

Mycotoxins are naturally occurring toxic metabolites produced by mycotoxigenic fungi on the different substrates on which they grow. Mycotoxin producing moulds may be present in raw materials, and the mycotoxins they produce are chemical compounds which cannot be physically removed from the raw materials once formed.

Where do mycotoxins come from?

Moulds are part of the natural ecology of the soil. Tillage methods such as minimum or zero-tillage leave organic matter at, or near, the surface of the soil, increasing the likelihood of the growth of systemic moulds. Insect damage, incorrectly set harvesting equipment, drying processes, and poor handling and storage of grain may render it more prone to the invasion of moulds. Harvesting grain when the moisture content is still high encourages mould growth. Grains can develop moulds which, when stressed either in the field or storage, produce toxins. Weather can affect which types of toxins are produced. For example, wet and cool seasons are more likely to produce vomitoxin (DON), zearalenone and T-2 toxin, while hot and humid conditions are ideal for the production of fumonisin and aflatoxin. Problematically, toxins can be present in feed even when no mould is visible.

What crops are affected by mycotoxins?

A wide range of plants and grain crops, including maize, groundnut, wheat, barley, rye, and oats can be affected by fungi that produce mycotoxins. These compounds are heat- tolerant and are not affected by the drying process of animal feed manufacture.

How many mycotoxins are there?

More than 400 mycotoxins have been identified and described. However, the focus of animal nutritionists is on the most toxic and prevalent mycotoxins: aflatoxins, ochratoxin A, patulin, fumonisins, zearalenone, and a group called trichothecenes (deoxynivalenol (DON or vomitoxin), nivalenol, T-2, and HT-2). Some of these fungal species produce more than one toxin, and crops can be affected by more than one fungal species at a time. Multi-mycotoxin contamination of grain crops tends to be the norm, not the exception.

What is the occurrence of mycotoxins in maize in South Africa?

The South African Grain Laboratory (SAGL) has been analysing maize and wheat samples since the 2003 - 2004 season for thirteen mycotoxins from all the production regions. The annual reports can be found on their website at https://sagl.co.za/mycotoxin/ for the last 18 seasons. The 2021 - 2022 reports are expected to be published shortly.

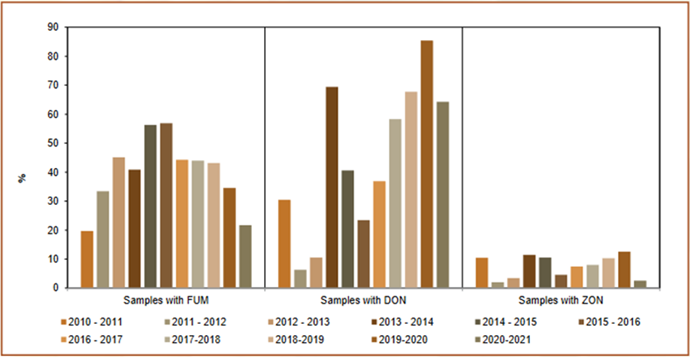

Below is a graph from the 2020 - 2021 report which shows the percentage of white and yellow maize samples that tested positive for the mycotoxins fumonisin, deoxynivalenol (DON) and zeralenone over the last eleven seasons.

• Fumonisin – 20 to 40 % of all samples tested positive.

• Deoxynivalenol – The number of samples testing positive has gradually increased from 10 % to about 60%. Since the 2017 - 2018 season, at least 60 % have tested positive.

• Zeralenone – 5 to 10 % of all samples tested positive.

• Aflatoxins – over the 18 seasons of testing, only 5 samples have tested positive for aflatoxin.

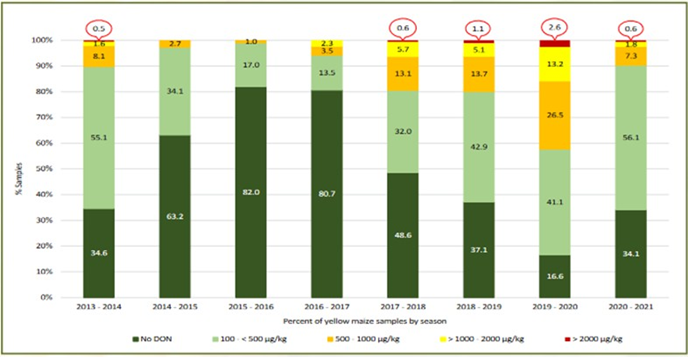

The graph below shows the DON concentration range in yellow maize samples over the last eight seasons. There has been an increase in the percentage of samples with higher DON levels. During this period, there has been higher summer rainfall and the occurrence of late rains well into the harvest season.

What are the regulations in South Africa?

Aflatoxin is the most regulated mycotoxin worldwide due to its carcinogenic properties and negative effect on the health of humans and animals. Many countries issue legal limits only with regard to aflatoxins for foodstuffs (including food crops), but some have also included fumonisin & deoxynivalenol limits for crops intended for human consumption. The maximum permissible levels (MPL) in parts per billion (ppb = µg/kg) for aflatoxin B1 for food- and feedstuffs in South Africa is shown in the table below.

|

HUMAN CONSUMPTION |

|

|

All foodstuffs |

5 |

|

ANIMAL CONSUMPTION |

|

|

Feed ingredients (with the exception of): |

|

|

Groundnut, copra, palm kernel, cotton seed, maize & products derived from processing thereof |

20 |

|

Complete feed for cattle, sheep, and goats |

50 |

|

Supplement/concentrate feed for beef cattle, sheep, and goats |

50 |

|

Complete feed for pigs and poultry |

20 |

|

Complete feed for other animals, young animals & pets |

10 |

|

Complete feed for dairy cattle |

5 |

|

Maize products intended for feedlot |

300 |

The maximum permissible levels (MPL) in parts per billion for fumonisin and deoxynivalenol in the regulation of contamination of foodstuffs (feed ingredients) are given in the table below.

|

FOODSTUFFS |

FUMONISIN B1 & B2 |

DON (Trichothecenes B) |

|

Poultry |

|

|

|

Cereal grains (wheat, maize, & barley) |

- |

2 000 |

|

Maize for further processing |

4 000 |

- |

The maximum permissible levels (MPL) in parts per billion for fumonisin B1, deoxynivalenol, ochratoxin A, zearalenone and ergot alkaloids in the regulation of contamination of feedstuffs (complete feeds) are given in the table below.

|

FEEDSTUFFS ON FULL RATION BASIS |

FUMONISIN B1 |

DON (Trichothecenes B) |

ZEARA- LANONE |

OCHRATOXIN A |

ERGOT ALKA- LOIDS |

|

Poultry |

|

|

|

|

|

|

Broilers |

50 000 |

4 000 |

- |

200 |

1 000 000 |

|

Layers |

50 000 |

4 000 |

- |

200 |

1 000 000 |

|

Swine |

|

|

|

|

|

|

Piglets / Weaners / Gilts |

- |

- |

3 000 |

- |

1 000 000 |

|

Growing |

10 000 |

1 000 |

5 000 |

50 |

1 000 000 |

|

Sows & Boars |

10 000 |

1 000 |

5 000 |

50 |

1 000 000 |

|

Cattle |

|

|

|

|

|

|

Calves (0 – 4 months) |

- |

2 000 |

500 |

- |

1 000 000 |

|

Dairy |

- |

3 000 |

500 |

- |

1 000 000 |

|

Beef |

50 000 |

5 000 |

- |

- |

1 000 000 |

|

Other |

|

|

|

|

|

|

Horse |

5 000 |

- |

- |

- |

1 000 000 |

|

Rabbit |

5 000 |

1 000 |

- |

- |

1 000 000 |

How do feed manufacturers manage the risk of mycotoxins?

1. Most commercial animal feed manufacturers have stringent purchasing standards and quality control procedures in place. Samples of all received loads of raw materials go through a series of quality control checks before a load is allowed to enter the feed mill and offload.

2. When it is not possible to refuse the load, it can be treated with physical and/or chemical treatments to reduce the contamination, or mycotoxin binders can be included into the final feed.

3. If it is possible, the contaminated ingredient can be stored separately and may be utilized to make feed for less sensitive species, or it may be diluted with a known quantity and contamination level of other feed ingredients to create an acceptable quality for compliance with feed regulations.

How can livestock producers manage the risk of mycotoxins?

The risk of animal feed being contaminated with one or more mycotoxins is always present. To manage this risk to the animals it is recommended that livestock farmers:

1. Be informed. Routinely discuss what risk factors the feed manufacturer may be experiencing with raw materials with your Technical Representative. Feed manufacturers routinely test for mycotoxins in raw materials to monitor the degree of contamination and they will be able to share the results of these tests with you. They will also be able to tell you whether they routinely include a mycotoxin binder in their products.

2. Where the contamination levels are low, feed manufacturers may not routinely include a mycotoxin binder in the feed as this adds cost and may make products more expensive than those of competitors. Consider asking for the inclusion of a mycotoxin binder in feed that will be fed to younger animals or breeding stock.

3. The Technical Representative can inform you about the mycotoxin products available and their cost. Most reputable suppliers of mycotoxin binder products offer a service of testing finished feeds and making recommendations on the correct product and inclusion level to assist you with managing the risk.

Should you require more information relating to mycotoxins in livestock feed please contact your De Heus Technical Specialist - https://www.deheus.co.za/meet-our-team/