Antibiotic-Free Broiler Production in South Africa: Challenges and Strategies

South Africa's broiler industry is a major contributor to national food security and economic activity. However, growing concerns about antimicrobial resistance (AMR), coupled with evolving international trade standards and consumer preferences, are driving a shift away from the use of antibiotics in poultry production. While South Africa has not yet enacted a full ban on antibiotic growth promoters (AGPs), the Department of Agriculture, Land Reform and Rural Development (DALRRD) is currently reviewing policies aligned with World Health Organization (WHO) recommendations and Codex Alimentarius guidelines. It is anticipated that antibiotics will increasingly be restricted to therapeutic use under veterinary prescription, with stringent record- keeping and oversight.

Retailers and processors are also beginning to establish private standards that require antibiotic-free certification for branded poultry products. In alignment with these trends, De Heus has initiated the "Natural Power" program, which encourages responsible antibiotic use and emphasizes improvements in animal health through nutrition, management, and hygiene practices.

This article seeks to promote proactive dialogue around the reduction and eventual elimination of AGPs in broiler production in South Africa. It explores the associated challenges, potential mitigation strategies, and productivity implications, while aligning with global trends and local realities.

Global Context and Relevance Globally, countries like Sweden, Denmark, and the Netherlands have banned AGPs and achieved success through improved farm management practices. The U.S. FDA followed suit in 2017, prohibiting medically important antibiotics for growth promotion. These international case studies demonstrate that, while transitional challenges exist, sustainable production is achievable through science- based strategies.

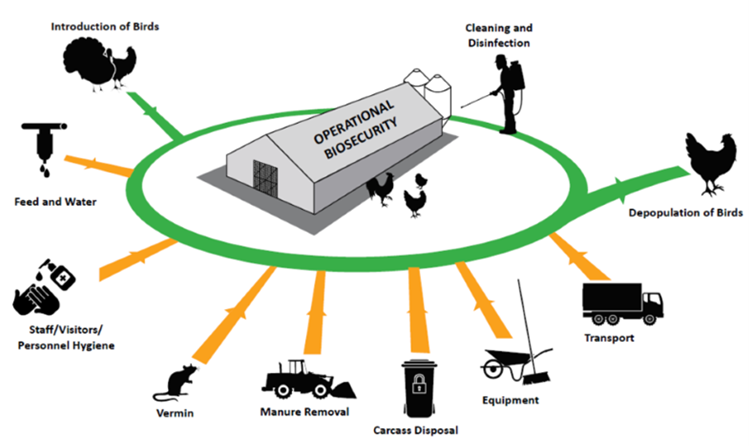

Biosecurity: The First Line of Defence

Farm Flow Design for Enhanced External and Internal Biosecurity

A well-designed farm layout is critical to minimizing disease introduction and spread. Key external biosecurity measures include perimeter fencing to restrict access, a single controlled entry point with security measures, and visible signage indicating restricted zones and biosecurity requirements. Visitor management protocols must include risk assessments, registration, and provision of protective clothing.

Designated parking areas should be situated away from broiler houses and feed storage, and vehicle disinfection procedures should be mandatory. Measures to exclude wild birds, rodents, and other pests are essential.

Internal biosecurity should involve zoning the farm into clean, dirty, and isolation areas, with strict separation of personnel, equipment, and animal movement. Dedicated tools and clothing per zone help prevent cross-contamination. Hygiene stations must be placed at building entrances, and all entries and activities must be documented, including visitor logs, disinfection schedules, and health records.

Challenges and Adaptation in the South African Context

Many small to medium-sized broiler farms in South Africa face structural and financial limitations in achieving full biosecurity compliance. These can be addressed through phased investment plans. Practical steps include:

1. Adoption of all-in/all-out systems with adequate downtime between flocks.

2. Comprehensive cleaning and disinfection between cycles.

3. Routine health monitoring and early disease detection.

4. Rodent and vector control programs.

Nutrition for Health and Performance Precision feeding in broilers aims to match daily nutrient requirements to support health and growth while minimizing the need for therapeutic interventions. Improper or excessive feeding can disrupt the gut microbiota, leading to enteric diseases, wet litter, and poor performance.

South African nutritionists must prioritize:

• High-quality, digestible protein sources.

• Balanced amino acid and micronutrient profiles.

• Use of functional feed additives such as probiotics, prebiotics, organic acids, phytogenics, and enzymes.

Impact on Performance Metrics: FCR and PEF

The transition away from AGPs is often accompanied by initial declines in performance in the initial transition phase. A collaboration between the veterinary services, nutrient suppliers and technical support on the farm will be essential to limiting the impact on performance. It is expected that the FCR with AGPs may range between 1.45–1.60, and the PEF with AGPs to be 300–330. These values are affected by increased susceptibility to subclinical infections, reduced nutrient absorption, and stress-related inefficiencies. Without AGPs, mortality and culling rates may rise, further depressing PEF. It is to be expected that farmers may lack the appetite to make the shift toward ABF production in a highly competitive market. It is beneficial to be an early adopter to stay above the curve and be prepared for the change. When the legislation changes and ABF production becomes law, early adopters will not be affected.

Mitigation Strategies:

• Reduce stocking densities to minimize stress and disease pressure in the broiler house.

• Adjust feed nutrient density to lower growth pressure while supporting gut health.

• Strengthen brooding and early-stage management.

• Enhance disease surveillance and vaccination program.

• Environmental and Litter Management.

Given South Africa's climatic diversity, effective environmental control in poultry houses is vital. Key practices include:

• Maintaining litter moisture at 20–25%.

• Keeping ammonia levels below 10-25 ppm.

• Ensuring a minimum ventilation rate of 1 m³/kg/hr.

• Regular cleaning and chlorination of water lines.

• Using tunnel ventilation systems to control temperature and humidity.

These actions reduce heat stress, moisture-related enteric disorders, and respiratory diseases.

De Heus’s natural power program is aimed at assisting farmers to systematically reduce the reliance on antibiotics, improve on-farm practices, and supply nutritional products that support the change and provide on- farm technical services for farmers to be better prepared for the inevitable changes in broiler production.

Conclusion

Antibiotic-free broiler production in South Africa is both a regulatory inevitability and a market-driven opportunity. Through the adoption of robust biosecurity, precision nutrition, environmental control, and effective management practices, producers can maintain competitive productivity and profitability. With the right support and commitment, the South African broiler industry can lead the continent in antibiotic stewardship while securing long-term animal health and food safety.

Get in touch with your local De Heus Specialist to learn more about unlocking your farm’s potential - https://www.deheus.co.za/meet-our-team