The importance of uniformity in laying hens

We often hear of uniformity being emphasised in broiler breeder and broiler production, where importance is placed on egg weights and body weights. Hatcheries prefer eggs that are more uniform for ease of hatching, and after the abattoirs require a bird of a particular size that fits the equipment. But how important is flock uniformity in modern layer production systems, and how do we achieve uniformity? It may come as a surprise, but uniformity can be a strong predictor for feed efficiency, rate of lay at peak production, persistency of lay and egg quality.

Feeding the flock:

As with all livestock, when we feed the modern layer, we can only cater to the average bird. Individual feeding is impossible on most commercial layer farms. This means when feeding, we essentially feed “one” bird, the average bird. Nutritional requirements, feed intakes and management practices are designed to suit the average hen and are not tailored to suit the needs of every individual hen. It is a “one size fits all” scenario. The more uniform a flock, the better this strategy will work, as feed allowances and nutrient compositions will meet the needs of the majority of the hens, and the more consistent the production will be. In most commercial laying systems, hens are allowed ad lib access to feed; however, trough fill and feeding times are often calculated based on the average hen’s intake. When uniformity is low and feed distribution is uneven, there is a risk that some areas in the feeders will run empty before the rest of the feeder line. Some hens will not have feed for a period, which may affect production. Figure 1 below shows a feeder line with varying feed levels; on the left, there is still an adequate level of feed in the trough, while on the right, there are patches of bare trough.

Figure 1: Varying feed levels in a gantry-fed feeder line

This system is gantry-fed, and provided that the gantry is functioning properly and uniformity is high, the feed should deplete at an even rate. Here, the uneven feed depletion may be due to a lack of uniformity across the shed. Alternatively, and possibly more likely, the uneven feed level may be due to the gantry distributing feed unevenly. Uneven feeding can lead to a decrease in uniformity as some hens are overfed and others are underfed. Overfed hens may become overweight and develop excessive fat pads that obstruct the reproductive tract, leading to laying complications; underfed hens may become underweight and struggle to meet their nutritional requirements and thus cease to lay. As uneven feeding continues, uniformity will worsen, and production will continue to suffer.

A lack of uniformity also leads to the lighter hens losing more condition and the heavier hens just getting heavier. Within a caged system, it is natural for a cage hierarchy to form, whereby the bigger and/or more aggressive hens will bully the smaller or lighter hens; this is especially true for cage systems where stocking densities and feeder space do not allow for all the hens to feed at the same time. Large variances in uniformity will result in the smallest hens consistently being bullied away from the feeders. Conversely, when uniformity is high, and hens are a similar size, feed competition is more well-regulated and less of a hierarchal feeding structure is seen.

Figure 2: Variation in laying hen size and body weight

While these factors are important during the laying period, they are even more crucial during the rearing period, where a lack of uniformity and thereby a lack of uniform feed intake will impact gut development, growth and skeletal development.

Sexual maturity and photo-stimulation:

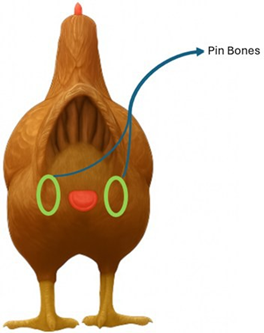

Arguably, uniformity has the greatest impact on sexual maturity. Photo-stimulation should begin when hens reach the target weight and not necessarily the target age. When photo-stimulation begins, all hens, no matter their size, will begin to be stimulated to lay. If uniformity is low, some hens will not be at the target weight when stimulation begins. These hens will not respond to the stimulation and will come into production later, produce smaller eggs, have increased chances of prolapse and vent issues, as well as increased chances of mortality from laying complications. Signs of sexual maturity include well-developed, red combs and wattles. Figure 3 shows a small, pale, underdeveloped comb on the left and a larger, brighter, more developed comb on the right, indicating a lack of sexual uniformity within hens of the same age. Figure 4 displays the rough location of the pin bones; a sexually mature hen will have a space of at least three to four fingers between these pin bones, while an immature hen will have just enough space for one or fewer fingers as a point of measurement between her pin bones. Consequently, there will not be enough physical space for the immature hen to lay an egg.

Figure 3: Variations in comb development

Figure 4: Schematic diagram of the rear of a laying hen

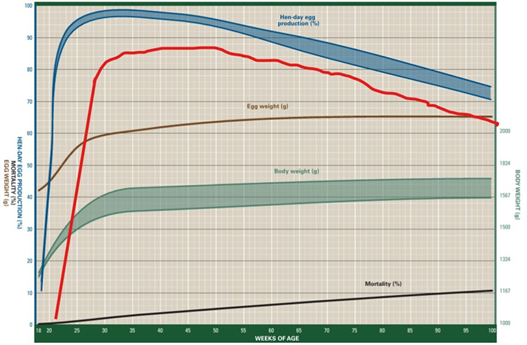

Photo-stimulating a non-uniform flock will not result in a rapid or synchronised onset of lay. The flock will often not have a defined production-peak but rather an extended point of lay, and a ‘flattened’ and lower production-peak will be seen.

Figure 5: Henday production with the red graph depicting a delayed flattened peak

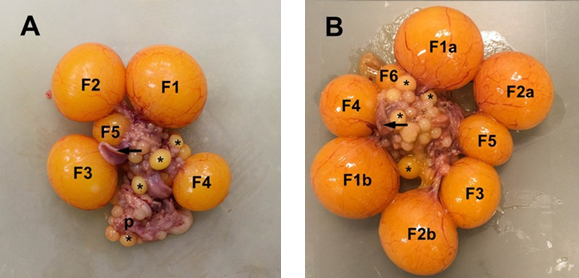

When physiologically immature hens are stimulated, this can lead to hormonal imbalances within the hen which affect egg production. The development of the ovaries can be disrupted, leading to disrupted follicular hierarchy, irregular ovulation patterns, increased incidence of internal laying, cystic ovaries and pauses between laying.

Figure 6: Variations in follicular hierarchy and development

Figure 6 shows two sets of follicular hierarchies, where follicles are denoted with the letter F in combination with a number; the lower the number, the higher up in the hierarchy the follicle. The arrow indicates where the last follicle was released. Figure A shows an irregular follicular hierarchy, hampered sexual development, health and or limited feed intake, whereas Figure B shows the normal desired follicular hierarchy of a sexually mature, healthy hen. Figure A would represent the lighter hens that were not stimulated correctly, that may have been bullied away from the feeders and did not meet their intake and nutrient requirements. These hens would be more prone to increased pause periods as follicles do not mature as rapidly as they should, and will be less productive layers.

Egg production and quality

A lack of uniformity has negative consequences on egg production and quality, and many of these issues stem from the effect of uniformity on sexual maturity, as previously discussed. Poor uniformity will result in a greater variation in egg size within the flock. Hormonal imbalances in immature hens that are stimulated can result in double yolks and “fairy eggs” (Figure 6). This happens as hens are designed to produce an egg and will do so even when going through hormonal imbalances, and an interruption or imbalance in hormones will not affect all hormones equally. For example, when levels of FSH and LH are low, ovum development and the release of a mature ovum will be hampered; however, progesterone and oestrogen will still be present. When an immature ovum moves down the oviduct, albumin formation and shell formation will still take place, resulting in a small egg. Eggshell thickness and colour may also be compromised in underweight hens that struggle to meet their nutritional requirements due to hampered intake and the cage hierarchy. Compromised shell quality, in turn, can result in an increased crack percentage. Non-uniform flocks may also have a decreased persistence of lay compared to more uniform flocks, as well as a flattened peak in production, as previously discussed.

Figure 6: Double yolk from 22-week-old pullet (left) & “fairy” eggs (right)

Management factors and achieving uniformity:

The easiest flock to manage is a uniform flock. Feed is used more efficiently with troughs emptying at an even speed, and nutrient uptake meets the requirements of each hen. All hens will experience the same microclimate and respond well to changes in environment, and feather pecking and bullying will be reduced. Disease detection can also be improved. It is not uncommon for the lighter underdeveloped hen, experiencing more stress, to be more vulnerable to disease; thus, a lack of uniformity can mask early disease signs as the “weak links” are taken out first, and these mortalities are not seen as unusual.

As discussed, uniformity affects several factors, but how do we achieve good uniformity? Achieving a good uniformity starts with good chick quality. Starting with higher uniformity is always better than trying to improve uniformity later. Figure 7 shows an example of size variation seen between chicks at placing.

Figure 7: Variation in chick size

In the rearing period, maintaining a high uniformity is dependent on early and equal access to feed and water as well as the correct temperatures, humidity and air quality. While farmers who buy in point of lay hens do not have much control over flock uniformity, there are a few management practices that can help maintain and even improve uniformity. Disease control, a good vaccination programme and good intestinal health management can help to maintain uniformity by reducing disease pressure and challenges that could affect only a portion of the flock and decrease uniformity. Regular weighing of hens will identify issues with uniformity, so that corrective steps can be taken early on.

If uniformity is found to be low with a large proportion of the flock being under the target weight, photo-stimulation should be delayed until the majority of the hens are at the target weight.

At the point of lay, hens can be weighed and placed based on weight to ensure that within a cage, hens are more uniform and bullying is reduced. Routine monitoring of feed distribution, water supply and house climate will aid in maintaining uniformity by ensuring all cages or areas in the house experience the same set of conditions, i.e. all hens have the same access to resources.

Uniformity may also be improved through reduced stocking densities to allow more equal access to feed and water during the laying period.

Conclusion:

Laying hen uniformity affects a range of factors, and it is also affected by a range of factors. Good uniformity is essential for efficient feed usage and conversion, egg production and management, as well as good hen welfare. A uniform flock is easier to manage and to feed. Birds with similar body weights and physiological development will all respond in a similar way to the same feed management, light stimulation and climate. Bullying will be reduced when flock uniformity is higher, while welfare and disease control will be improved. High uniformity results in more consistent, sustained egg production with increased egg quality and strong peak production. Laying hen uniformity is a crucial factor in determining the success of a laying operation.

Should you require more information relating to The importance of uniformity in laying hens , please contact your nearest De Heus Technical Specialist - https://www.deheus.co.za/meet-our-team/.